Autoclave glue

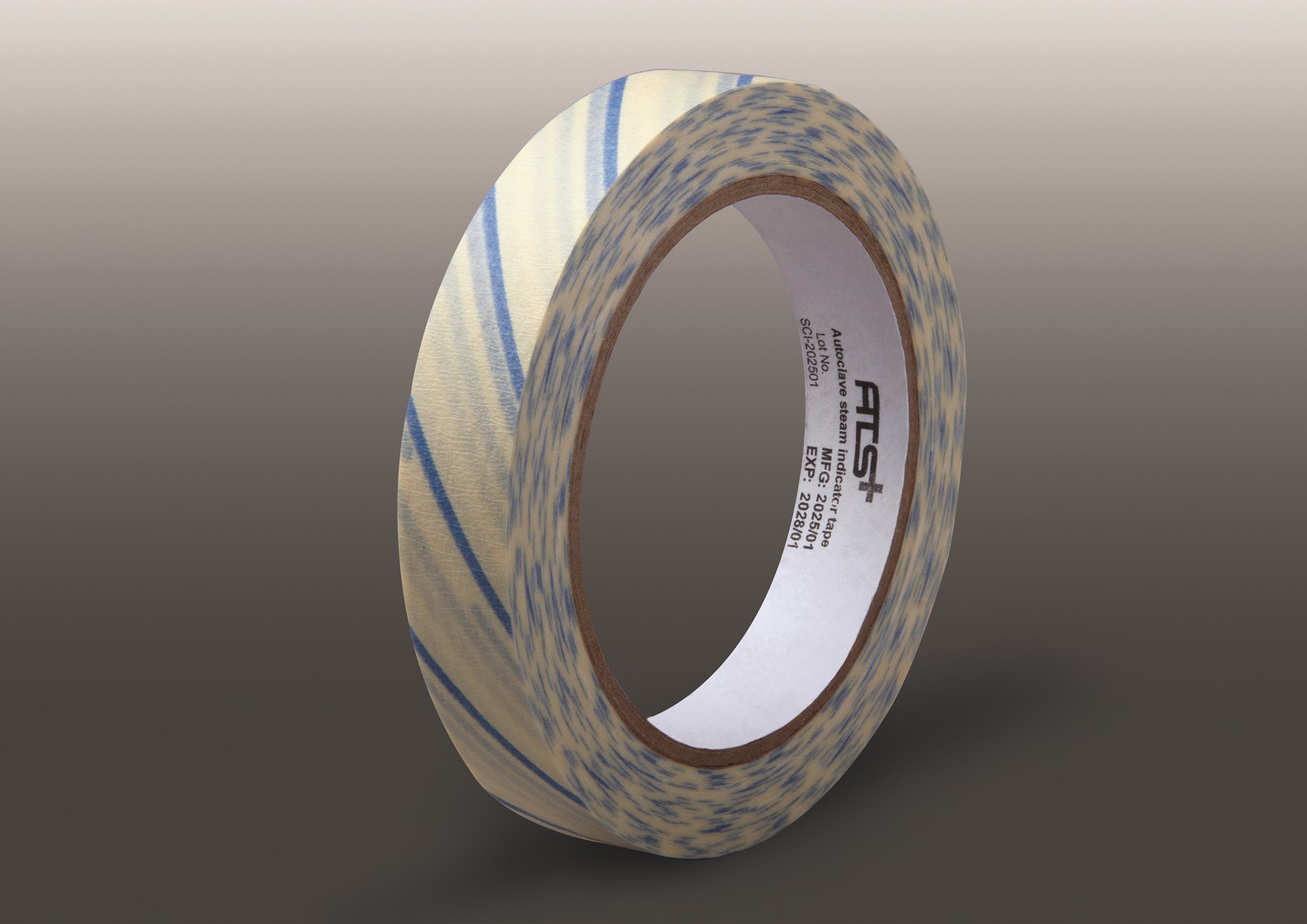

Autoclave tape is a vital tool in the sterilization process of medical and laboratory equipment.

Autoclave tape is usually supplied as a steam-sensitive tape. It not only plays a role in packaging and sealing sterile packs, but also, by changing its color, is an effective indication that the equipment has passed the autoclave cycle.

Accurate knowledge of this product is essential for technical personnel, CSSD technicians, and purchasing managers of medical centers.

?What is autoclave glue

Autoclave Tape is a thermal adhesive tape used to indicate the sterilization process in autoclaves. It is usually made of a crepe paper or cloth backing, coated with a heat and steam sensitive adhesive, and strips of temperature and moisture sensitive chemicals.

This adhesive is made from lead-free materials, has high adhesion, and easily sticks to paper, fabric, and sterile packages without leaving any residue.

This product is manufactured in accordance with international standards ISO 11140-1 and ensures high safety and efficiency for healthcare centers.

When exposed to specific autoclave conditions (temperature 121 or 134 degrees and specific pressure), the lines on the adhesive change color, indicating that the process has been performed correctly.

Structure and composition of autoclave adhesive

Autoclave adhesive is composed of several specialized layers, each of which plays an important role in its accurate and safe performance:

Base layer (backing): Usually made from crepe paper with high tensile strength.

Pressure Sensitive Adhesive (PSA): This adhesive is designed to adhere tape to sterile packs and must be resistant to temperature and steam.

Indicator Ink: Contains heat-sensitive chemicals such as mercaptans and heavy metals that change color (usually from blue to black or brown) when they reach autoclave temperatures.

Protective cover (on some models): Used to prevent moisture penetration and protect vapor-sensitive ink.

Autoclave adhesive producing countries

It is produced in several countries, but the main suppliers to the global market and Iran are from these countries:

Iran: Domestic production with acceptable quality and competitive price

Germany and Finland: High quality, under European standards

China: Wide variety with low price, variable quality

Turkey: Medium to high quality with mid-range price

Italy: Reputable brands focusing on the specialized hospital market

In Iran, Azin Teb Spanta Company, with the official logo registered (Salamat Sazan), currently produces and supplies two types of autoclave adhesives: ATS and Salamat Sazan autoclave adhesives.

ATS adhesive, as a high-quality product with precise color change performance, is mostly used in large medical centers and hospitals; while Salamat Sazan adhesive, while maintaining the necessary standards, is considered a more economical option for smaller medical centers and clinics.

Autoclave Glue Models and Features

Adhesives are divided into the following categories based on various criteria:

Based on operating temperature: 121°C (1 atm pressure):

For more sensitive packs 134°C (2 atm pressure):

For complete sterilization with pressurized steam

Based on adhesive width: 12 mm 19 mm 25 mm 50 mm

The wider it is, the more suitable it is for larger and heavier packs.

By marker type: Single stripe

Multi-stripe

Block or printed logo

Special features: Moisture-proof

Latex-Free

Lead-Free

Writable with marker

How to produce autoclave glue

Producing this type of adhesive requires a specialized process in a controlled environment:

Preparing a crepe or textured fabric substrate

Applying a layer of pressure-sensitive adhesive to the underlying surface

Printing vapor-sensitive materials on the upper surface (thermal marker)

Chemical curing and ink fixation at a specific temperature

Cutting rolls to standard sizes (19, 25, 50 mm)

Packaging in rolls of 50, 60 or 100 meters

Criteria for selecting the right sterilization adhesive

To choose the best autoclave adhesive, consider the following criteria:

Color change accuracy: Must react correctly at a specific temperature and in the presence of steam.

Adhesive strength: To prevent the packs from opening during autoclaving.

Suitable width and length: Suitable for the dimensions of the pack and the sterilization device.

Amount of adhesive residue on the pack: There should be no adhesive residue.

Valid certificates (CE, ISO, Ministry of Health)

Important points when using autoclave glue

Glue should only be used for fabric or paper packs, not for metal or plastic surfaces.

A change in the color of the adhesive indicates that the sterile cycle has passed, not that the contents have been completely sterilized.

Avoid storing the adhesive in humid environments or in direct sunlight.

Although it may seem simple, this type of sterilization adhesive is one of the important safety elements in the sterilization process. Choosing the right brand, knowing its structure and quality of performance, plays an important role in ensuring the health of patients and the credibility of medical centers.

By improving quality, Iranian brands have been able to meet domestic needs to a large extent, while European brands are still the first choice for super-specialty centers.

If you are a purchasing manager or CSSD expert, it is recommended to always purchase certified and tested adhesives and avoid buying uncertified and cheap samples.